Consultation hotline:

(+86)0532-88988868

(+86)0532-88988868

Reverse osmosis equipment, also known as water purification equipment, has high requirements for desalination rate in many industries when using water purification equipment.

1、 In reverse osmosis equipment, the electrodialysis device is combined with other water treatment equipment to form a desalination system

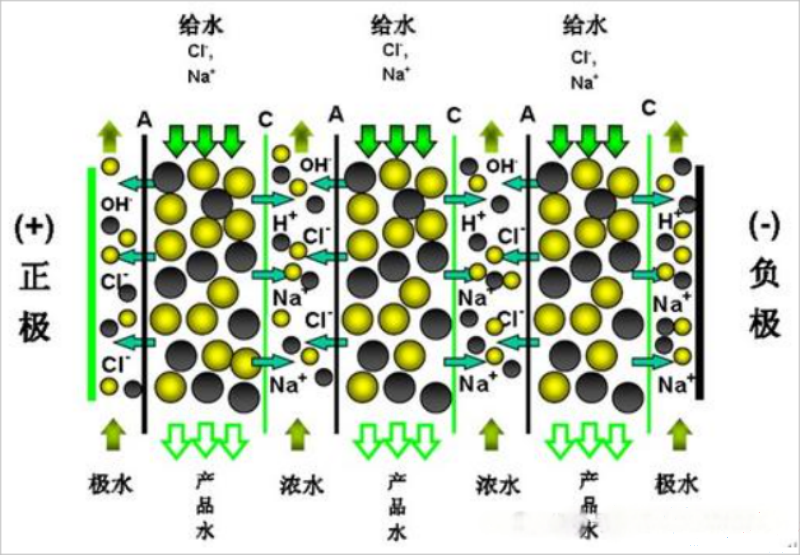

Electrodialysis is generally used for local desalination of high salt content and high hardness saline water, and for deep treatment of deep desalination.

Due to the application scope of electrodialysis desalination, it is necessary to combine ion exchange water treatment technology with the requirements of raw water quality and desalination water quality in order to fully leverage their respective advantages in the water treatment process and achieve reasonable technical requirements. Economic benefits and stable operation. The commonly used reverse osmosis equipment systems are as follows.

1. The pre-treatment electrodialysis ion exchange system, which combines electrodialysis and ion exchangers, has been widely used both domestically and internationally. The principle of its combination is that when the resistivity of water is above 20 * 104_ucm, the electrodialysis device is prone to polarization and cannot continue to adapt; On the contrary, ion exchange can adapt to the treatment of low salt water and produce high-purity water. Therefore, in this combined water treatment system, electrodialysis is used as a pretreatment for ion exchange water treatment to remove most (60% -90%) of the salt in the raw water, and the remaining small portion can be further removed through ion exchange to produce desalinated water. According to the requirements of desalinated water quality, ion exchange can be carried out in single bed, double bed, mixed bed or other different combination forms. The system has good effluent quality, stable operation, low dosage of regenerant, and strong adaptability to changes in the salt content of raw water. Suitable for coastal areas affected by saltwater or seawater recharge. The joint desalination water treatment system has been widely used in fields such as power, chemical, light industry, and electronics.

2. Pre treated ion exchange electrodialysis

3. Pre treated ion exchange (softening), electrodialysis ion exchange (softening)

In this reverse osmosis equipment combination system, ion exchange softening treatment is carried out before and after electrodialysis, because pre softening can prevent scaling and blockage of electrodialysis, and improve the desalination efficiency of electrodialysis. Ion exchange softening treatment after electrodialysis can further reduce the hardness and relative alkalinity of water, ensuring the quality of feed water for medium and low pressure boilers.

In this reverse osmosis equipment combination system, ion exchange softening treatment is carried out before and after electrodialysis, because pre softening can prevent scaling and blockage of electrodialysis, and improve the desalination efficiency of electrodialysis. Ion exchange softening treatment after electrodialysis can further reduce the hardness and relative alkalinity of water, ensuring the quality of feed water for medium and low pressure boilers.

Application of electrodialysis in water treatment

Treatment of brackish water and seawater desalination, seawater concentration for salt production, pure water preparation, industrial wastewater (electroplating wastewater, papermaking wastewater, heavy metal wastewater), radioactive wastewater, reverse osmosis equipment, ion membrane electrolysis, etc.

Two. The process system of the electrodialyzer body in the reverse osmosis equipment

Selecting an economical and reasonable electrodialysis process system (i.e., desalination method) of reverse osmosis equipment is an important part of electrodialysis desalination process design. Generally, it should be determined by technical and economic comparison according to the raw water quality, quantity and water quality requirements.

The commonly used desalination methods in reverse osmosis equipment include direct current method, circulation method, and partial circulation method.

1. Direct current desalination of reverse osmosis equipment:

After passing through one or more series connected electrodialysis devices, the raw water can achieve the required water quality. Suitable for situations where the water volume and raw water concentration are constant. The advantage of this method is continuous water supply and simple pipeline. The disadvantage of this method is that the effluent quality of the standardized equipment varies with the salt content of the raw water.

2. Reverse osmosis equipment cycle desalination:

The raw water is recycled multiple times in the electrodialysis device and water tank to achieve the desired effluent quality. Its advantages are that regardless of changes in the concentration of the raw water, the raw water can be treated to any desired level, with high flow rate, fast desalination rate, and small volume of the electrodialysis device. Its disadvantage is that it requires the installation of a circulation pump and a water tank, which can only supply water intermittently and consumes a lot of electricity. Suitable for small equipment with low production water volume, high salt content in raw water, and high requirements for effluent quality.

3. Partial circulating desalination of reverse osmosis equipment:

It is a combination of direct current seawater desalination and circulating seawater desalination. In some circulating desalination process systems, the effluent fresh water from the electrodialysis device is divided into two ways: one is continuous effluent for user use, and the other is returned to the electrodialysis device to mix with the water in the aqueous phase and continue desalination. Its characteristic is the use of standardized equipment, which can meet the requirements of different water quality and quantity. When the salt content of the raw water changes, the circulation can be adjusted to ensure stable effluent quality, but the system is complex and energy consumption is high. Suitable for large-scale water treatment systems.