Consultation hotline:

(+86)0532-88988868

(+86)0532-88988868

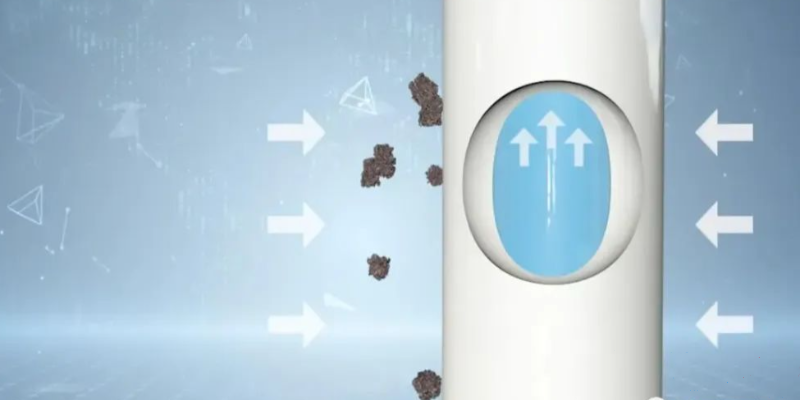

Vertically installed hollow fiber ultrafiltration membrane modules mostly adopt the operation mode of water inlet, water production and concentrated water. In addition, there are lower inlet water, lower produced water, and upper concentrated water; Upper water inlet, lower water production, lower concentrated water and upper water inlet, upper water production, lower concentrated water and other operation modes. When the air cannot be effectively removed, not only the efficiency of the components and pipes will be reduced, but also water hammer will occur during the start and stop of the system due to the compressible nature of the air, resulting in serious damage to the membrane module.

The most effective way to drain the air in the hollow fiber ultrafiltration membrane module is to use the lower inlet operation mode, and the air in the hollow fiber ultrafiltration membrane module will be pushed up from the bottom to the concentrated water pipe and water purification pipe at the top of the hollow fiber ultrafiltration membrane module with the inlet water and then discharged out of the system. However, when the upper water inlet operation mode is adopted, because the density of water is higher than that of gas, a considerable part of the gas will be kept in the cavity of the component and difficult to be discharged, or the work efficiency of the component will be reduced, or the air bubbles will be entrained in the clean water or concentrated water runoff during the system operation and commissioning process for a long time, and it is difficult to make the system enter a stable state.

The reason why most MBR membrane systems adopt the upper water production mode is that it is convenient for the air to be discharged from the water purification area of the membrane module, and the second is to facilitate the balanced water production flux at the beginning and end of the module