Marketing Hotline:

(+86)0532-88988868

(+86)0532-88988868

One. Pure Water (DI Water)

1. Applications: Pure water for IC industry cleaning; ultrapure water for OLED cleaning; ultrapure water equipment for solar photovoltaic use; ultrapure water equipment for optoelectronics industry; ultrapure water equipment for semiconductor industry; industrial ultrapure water equipment for monocrystalline silicon/multicrystalline silicon/silicon materials/solar cells; pure water equipment for LCD displays; ultrapure water equipment for LED optics; ultrapure water equipment for glass coating; ultrapure water equipment for optical lens cleaning; ultrapure water equipment for thin-film solar cells and multicrystalline ingot production; EDI (Electrodeionization); and ultrapure water treatment equipment for various industries.

2. Features: In equipment design, mature, reliable, advanced, and highly automated two-stage RO + EDI + mixed-bed deionization water treatment process is adopted; full membrane method process: UF, second-stage RO, EDI, polish mixed bed. Ensures treated water resistivity reaches above 18 MΩ·cm, meeting the requirements for product quality!

Two.Desalinated Water

1. Applications: Water treatment equipment for boiler makeup water softening in thermal power plants and medium to large industrial and mining enterprises, boiler softening and demineralized water equipment, reverse osmosis desalinated water treatment systems, water-steam circulation systems in thermal power plants, circulating cooling water equipment for air conditioning and cold storage, and other industrial circulating water treatment equipment.

2. Features: Utilizes the world's most advanced reverse osmosis membrane elements, pressure vessels, and other equipment, equipped with reasonable pre-treatment and post-treatment systems, capable of producing water that meets the high-pressure boiler makeup water standards in the power industry. The control system uses an industrial computer program control, enabling automatic start/stop, dosing, and flushing, as well as automatic monitoring of various operating parameters for production management.

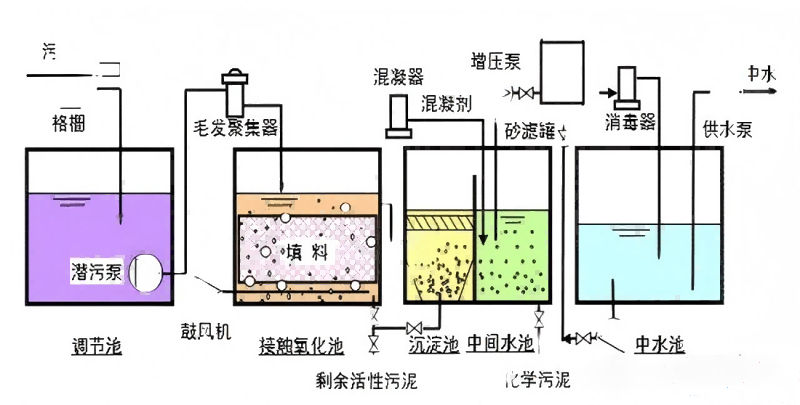

Three.Reclaimed Water Treatment

1. Applications: Reuse of water in electroplating, electroplating wastewater treatment and reuse equipment, printed circuit board wastewater treatment and reuse, textile wastewater treatment and reuse, liquid crystal display wastewater reuse, food wastewater treatment and reuse, electronics and semiconductor wastewater reuse technology, paper wastewater treatment and reuse, municipal sewage treatment and reuse.

2. Features: Uses a complete membrane treatment technology consisting of continuous microfiltration, ultrafiltration, and reverse osmosis membranes, forming a unique and complete treatment process. It ensures stable effluent water quality while recovering useful metals to create benefits for enterprises. The design is fully customized according to customer requirements. Major components use world-renowned branded products, with advanced technology, reliable performance, and excellent water production performance.

3. Types: Reverse osmosis pure water treatment equipment, deionized water equipment, ion exchange mixed bed equipment, deionized water equipment for surface treatment, pure water equipment for PCB electroplating lines, water for fertilizer production, chemical water, pure water equipment for daily cosmetics, purified water equipment for pharmaceutical raw materials and intermediates, pure water equipment for bioengineering, pure water equipment for metallurgical and chemical uses.

Four.Well Water Treatment

1. Applications: Tap water turbidity removal equipment, river water purification equipment, groundwater and deep well water iron and manganese removal equipment, multi-media filters, activated carbon filters, disc filters, gravity valve-less filter pools, perforated cyclone reaction sedimentation tanks. Features: Uses advanced, efficient, scientific, and cost-effective process combinations from domestic and international sources, mainly to remove harmful substances such as iron, manganese, ammonia nitrogen, sediment, and scale, ensuring that the treated water meets national drinking water standards.

2. Types: Factory direct drinking water equipment, purified water and mineral water production equipment, pipeline direct drinking water system projects, factory and enterprise employee drinking water equipment, community and building separated water supply systems, reverse osmosis purified water equipment, ultrafiltration mineral water equipment, natural water production equipment.

3. Features: Further processes municipal tap water into purified water that meets the national bottled drinking water quality standards. Through a dedicated high-quality water supply pipeline system, it is delivered to households or office drinking points, providing fresh, clear, cleaner, and high-quality purified water without secondary pollution.

Five.Household Water Treatment

1. ClassificationHousehold water treatment systems include three parts: central water purification system, central water softening system, and central pure water system. The central water purification system first effectively removes chlorine, heavy metals, bacteria, viruses, algae, and suspended solids from the water, and then uses activated carbon to further remove various organic substances, making the water clear, clean, halogen-free, and safe for direct drinking; the system also features automatic maintenance functions. The central water softening system replaces calcium, magnesium, and other ions in the water with natural resin, reducing water hardness; it effectively minimizes wear on clothing and skin and prevents scaling problems in pipes, fixtures, and bathroom equipment. The central pure water system uses reverse osmosis and a precisely calculated five-stage filtration process, turning the water into pure water free of any impurities and minerals.

2. Features

A. Central Water Purification System:

a. Can remove chlorine, heavy metals, suspended solids, etc. from water;

b. Has sterilization function;

c. Removes various organic substances through activated carbon and can be consumed directly;

d. The system has an automatic maintenance function.

B. Central Water Softening System:

a. Uses natural resin to replace calcium and magnesium ions in water, reducing water hardness;

b. Reduces damage to clothes and skin caused by minerals in water;

c. Prevents scale formation in pipes, valves, bathroom fixtures, and household appliances, extending their service life;

d. Prevents mineral stains on sanitary ware, tableware, etc.

C. Central Pure Water System:

a. Uses reverse osmosis with a precisely calculated five-stage filtration process;

b. The treated water becomes pure water, containing no impurities or minerals.