Marketing Hotline:

(+86)0532-88988868

(+86)0532-88988868

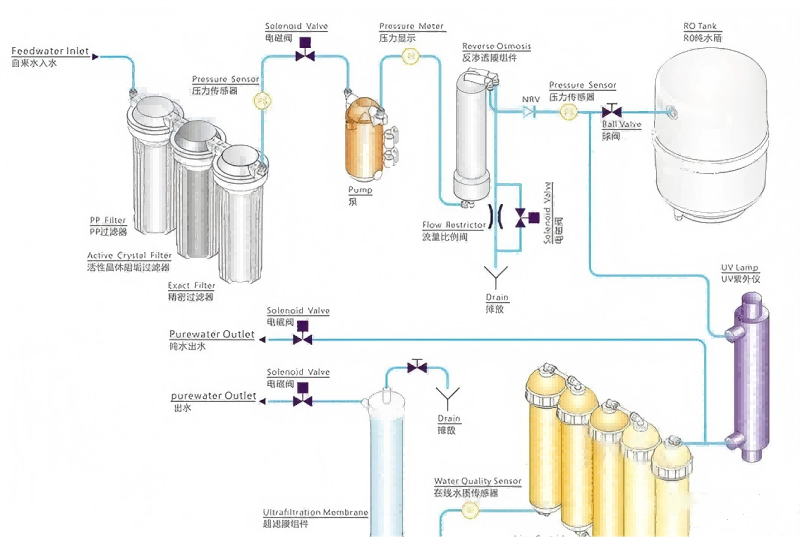

High-pressure pumps play a crucial role in reverse osmosis systems, serving as an essential guarantee for processes such as pretreatment, reverse osmosis, water supply, and flushing. Therefore, selecting durable pumps is of utmost importance in reverse osmosis equipment. High-pressure pumps are closely related to the water supply pressure. When the system is initially put into operation, achieving the designed water production rate does not require very high pressure, so there is ample pressure from the water supply pump during initial operation; however, over time, wear on the pump will gradually reduce this excess pressure, and the efficiency of the reverse osmosis system will similarly decline.

So, how can we solve this problem?

As we know, the standard reverse osmosis product water contains almost no impurities, as there is no issue of membrane element contamination. However, in practical applications, apart from the secondary reverse osmosis system, where the feed water is sourced from the product water of the primary reverse osmosis system, the feed water for other reverse osmosis systems is almost always raw water that has been pre-treated through ordinary processes. Although the pre-treatment process removes some impurities, the quality of the feed water is still inferior compared to the water source used under standard testing conditions. Therefore, the design production capacity of the membrane element should be less than the standard production capacity; if it is still designed based on the standard production capacity, the reverse osmosis membrane elements will soon become contaminated, leading to membrane damage.

We know that manufacturers select different design production capacities to design membrane elements based on the different sources of feed water. However, contamination of the reverse osmosis membrane elements is inevitable and will gradually occur with continuous use of the equipment. Of course, we can partially restore their performance through chemical cleaning, but it is difficult to fully restore their performance.

Therefore, during the design phase, one should choose a supply pump that can ensure it reaches the designed production capacity three years later, meaning a higher pressure supply pump needs to be designed.Thus, to achieve this goal, there should be a manual adjustment valve set behind the high-pressure pump to regulate the feed water pressure, or a variable frequency adjustment device should be set for the feed water pump to adjust the feed water pressure using variable frequency methods, so that the pump can be durable and meet the expected water supply objectives.

The manual adjustment valve behind the high-pressure pump generally does not require frequent adjustment after being set. It basically maintains a constant position over a period of time, and there is no need to open or close this valve during each system startup.

However, if there are no other valves behind the high-pressure pump, the high-pressure water source from the pump will directly impact the membrane component each time the system starts. This can lead to 'water hammer' phenomena, especially when there is air in the system, which can easily cause the membrane component to break.

To prevent the occurrence of the above phenomenon, an electric slow-opening door should be installed after the high-pressure pump. After starting the high-pressure pump, the electric slow-opening door should be slowly opened, gradually applying pressure to the reverse osmosis membrane in the system. The electric slow-opening door should be a fully open and fully closed valve, and its opening and closing time can be adjusted, but it is generally set to 45 to 60 seconds. Therefore, from the safety perspective of the reverse osmosis membrane components, an electric slow-opening door should be installed.