Marketing Hotline:

(+86)0532-88988868

(+86)0532-88988868

Problems with boiler water treatment

1 Boiler water treatment was not implemented

At present, some boilers often do not get people's attention because the capacity is relatively small or only used in winter, and those who manage small boilers often have insufficient experience in boiler water treatment, and there is no effective boiler water treatment for small boilers in the process of boiler management, so that the boiler is scaled or corroded, and over time it has a serious impact on the management of boilers.

2. Improper boiler water treatment method

At present, many enterprises often adopt unscientific methods for the treatment of boiler water in order to save greater expenses, and various tools and instruments used in the process of boiler water treatment do not meet the relevant regulations, such as "three no" electronic anti-scale instruments and anti-scale agents.

In terms of personal interests, this approach can not only reduce the cost of chemicals but also eliminate the expenses of water quality analysts, but it cannot fundamentally solve the problem of boiler fouling and corrosion, and at the same time not only causes waste of energy but also reduces the service life of the boiler.

Moreover, if the antiscalant is used improperly, it will also have the opposite effect on the protection of the boiler, accelerate the scaling and corrosion of the boiler, and bring a serious threat to the normal operation of the boiler.

3 Failure to pay attention to the pH value of boiler water

Generally, for steam type boilers, the hardness index of feed water is very important, and the hardness of boiler water often affects the scale and corrosion problems in the later stage.

If the hardness of the boiler water is high, the boiler water will scale due to evaporation, and the hot water boiler will be relatively more susceptible to corrosion.

4 Boiler water treatment equipment problems

If the quality of the effluent from the water treatment equipment used in the treatment of boiler water is not good, and the effluent efficiency is not high, it will often accelerate the scaling and corrosion of the boiler. The main reason for this is that the resin is damaged by improper use, and eventually oxidation; or the inner wall of the iron boiler has not been treated in a timely and proper manner, resulting in iron poisoning in the resin; Or the river water is not filtered before being used as boiler water, so that the resin is clogged with silt and cannot function properly.

5. The water quality laboratory management is unqualified

The relevant units did not formulate strict rules and regulations for the boilers used, and some conventional indicators, such as boiler feed water and boiler steam, were not clear; At the same time, some water quality testing personnel have low quality and a weak sense of responsibility, and do not pay attention to the data of water quality testing, and even more will falsify the relevant data to cope with the inspection of the higher authorities.

6. Improper treatment of boiler blowdown

At present, there are often two problems in the process of sewage treatment of boilers: on the one hand, boiler workers do not discharge the boiler in order to reduce the heat loss in the sewage discharge process; On the other hand, the boiler blowdown personnel pay too much attention to the quality of the boiler, resulting in excessive blowdown, resulting in serious heat loss.

Solutions to boiler water treatment problems

1) For those who do not implement boiler water treatment, the boiler, boiler water and local conditions should be comprehensively considered. For those steel-shell boilers with small evaporation and small steam pressure, the method of chemical treatment outside the boiler should be carried out as much as possible, and the corresponding deaeration equipment should be equipped for deaeration treatment as much as possible;

For those boilers with large evaporation and large steam pressure, chemical treatment should be given to the boiler, and the corresponding oxygen removal instrument must be installed; For the situation that natural water contains more impurities, sedimentation or filtration and other measures should be used to give effective treatment, and boiler water treatment should be realized in a timely and efficient manner;

2) For the improper treatment method of boiler water, the treatment method of boiler water should be readjusted, and the use of new technology needs to be approved by relevant departments and reported to the local labor department for filing, so that the new technology can be treated on the designated boiler.

If the boiler water treatment has obtained good results, it will be promoted after passing the technical appraisal of the superior department, so as to ensure that the boiler can be used safely;

3) The pH of the boiler water should be adjusted to reduce the probability of boiler fouling and corrosion. Generally, the PH value of boiler water should be kept between 10~12, if the hardness of boiler water is too large, soda ash should be appropriately supplemented to increase its PH value to a suitable range;

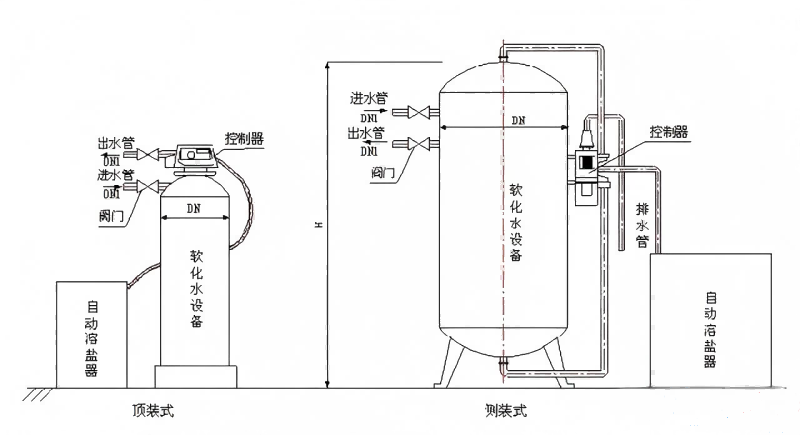

4) Appropriate measures should be taken for the unqualified boiler water treatment equipment. For example, when using resin exchanger, the method of chemical treatment outside the boiler should be adopted, and the situation of resin iron poisoning should be reasonably analyzed according to the corresponding situation, the cause of the occurrence should be found out and the appropriate plan should be studied to resuscitate the resin, and regular anti-corrosion and inspection should be done;

5) For the situation that the management of boiler water quality testing is not clear, it is necessary to strengthen the treatment of boiler water quality, and the department leaders should be fully aware of the importance of boiler water treatment in the process of boiler safety and long-lasting operation, and at the same time, boiler water treatment should be included in the routine management, and regular training and assessment should be given to water quality treatment personnel and boiler management personnel, especially for those water quality inspectors to carry out boiler water treatment knowledge education;

Boiler water treatment personnel should strictly follow the relevant water treatment regulations for water treatment, strengthen education in ideology, obey the distribution in the post, strictly abide by the discipline, the boiler water test should be timely, accurate and comprehensive, and be able to fill in the test results correctly, can not deceive the inspection of superiors, refuse to implement any violations and be able to work rigorously;

The test of boiler water quality should follow the relevant regulations, and the hardness, alkalinity and pH value of the raw water should be measured at least every month, and the hardness of soft water quality and other items should be tested 1~2 times per hour, and the relative alkalinity of boiler water and dissolved solids should be checked regularly, and at the same time, under the condition of completing the basic work, it should also be responsible for guiding the sewage discharge work of the boiler;

6) For the situation of improper boiler blowdown, the boiler blowdown policy should be improved. At the same time, the boiler with the bottom regular sewage discharge and the surface continuous sewage discharge two devices need to be discharged at least once per shift, and the boiler water should be tested every 1 hour ~ 2 hours to analyze whether the indicators meet the relevant standards, if a certain item is found to exceed the standard in the test, the valve should be adjusted immediately until the index reaches the standard;

For those boilers with bottom sewage device but no surface sewage device, at least once per shift, the overall alkalinity and PH of the boiler water should be carefully analyzed, and if a certain index is found to be beyond the normal level, the number of bottom discharges should be increased.