Marketing Hotline:

(+86)0532-88988868

(+86)0532-88988868

Nitrogen and phosphorus removal is an important function of the sewage treatment system, and it is very important to ensure that the nitrogen and phosphorus removal treatment meets the standards. As the saying goes, if a horse runs fast, it must eat more grass.

For example, effective denitrification requires a carbon source that is easily biodegradable, biological phosphorus removal requires short-chain volatile fatty acids, and in some areas where natural water quality is soft, alkalinity needs to be supplemented to maintain the pH conditions required for the nitrification process of the entire aeration tank; In addition, if chemical phosphorus removal is used, either as a complement to the biological phosphorus removal process or as the primary means of phosphorus removal, metal salts and polymers need to be added.

Carbon source addition for denitrification

1. When do I need to add medicine?

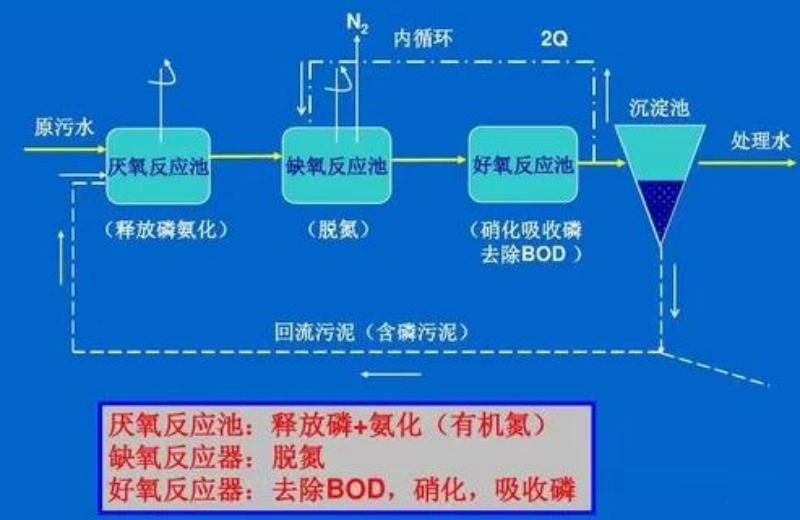

Biological denitrification requires the completion of two processes: nitrification and denitrification. Ammonia nitrogen in wastewater must first be nitrified or converted to nitrite and nitrate, and then in the denitrification process, the nitrate will be reduced to nitrogen gas as an oxygen donor for oxidizing simple carbon compounds during cellular respiration.

Therefore, the denitrification process with the goal of nitrate removal must have a carbon source that is readily biodegradable. Sources include solubility BOD in influent water, cell decay during endogenous denitrification, and reflux of various supernatants. When the influent dissolved organic matter is insufficient and denitrification requirements are high, chemicals need to be supplemented to provide the carbon source required for the denitrification process.

2. What are the carbon sources? Where is the dosing to?

The artificial carbon sources used in denitrification include pure chemicals such as methanol, ethanol, denatured ethanol, acetic acid and sodium acetate, or waste sugar, molasses and waste acetic acid solutions in industrial production processes. Methanol is the most widely used and has proven to be the most suitable carbon source.

For the conventional biological denitrification process, methanol should be directly added to the anoxic section, and fully mixed with the inlet water and the mixed liquid through the agitator in the anoxic section, so as to prevent the violent turbulence of the water flow from volatilizing methanol from the liquid phase to the air, and also to prevent part of the methanol from being consumed by bacterial aerobic respiration due to the presence of excess oxygen.

If the sewage plant adopts a four-stage or five-stage activated sludge process, the addition of a carbon source in the subsequent anoxic section (the second anoxic section) can obtain a higher denitrification rate than endogenous respiration, which can further remove nitrate; For tertiary denitrification systems, such as denitrification filters, denitrification aerobic biological filters, etc., supplementing the carbon source is very important for the operation of the system.

Because the denitrification process is downstream of the main aeration process, all dissolved BODs have been removed from the feed water, so methanol is usually added to the denitrification feed water.

3. How to calculate the dosage?

The amount of methanol is affected by nitrate (NO³-N), nitrite (NO2-N) and dissolved oxygen. The amount of methanol required can be calculated by equation (1).

Methanol requirement:

2.47NO³-N+1.53NO2-N+0.87DO (1)

In actual operation, it is usually considered as adding 3 mg/L methanol to 1 mg/L nitrate for every denitrification removal, and then adjusted according to the actual load and operation of the sewage plant. Proper control of methanol dosage is important for the operation of a tertiary denitrification system.

Overdosing not only wastes chemicals, but also increases the concentration of BOD in the effluent of the denitrification system. This is not too much of a problem for wastewater treatment plants where the effluent BOD concentration is not required, but it is a major concern for wastewater treatment plants with BOD limits of about 5 mg/L or less.

4. Safety measures for methanol dosing system

With a flash point of 12 °C, methanol is a highly flammable substance. Methanol storage tanks, pipelines and their accessories, and electrical systems need to be protected from explosions. Methanol dosing systems should usually be installed outdoors and away from other equipment. The methanol storage tank should be fitted with a floating top cover and a pressure relief valve and fire extinguisher.